A 2018 market study by Skylogic Research identified the survey and mapping industry as the most profitable of all UAV business segments. Given the lucrative nature of this business many UAV professionals are looking to offer UAV survey, mapping and GIS services, however, it is not as easy as simply mounting a camera to your UAV platform and taking pictures.

So, what do you need to know about turning your UAV into a professional mapping solution?

First, recognize that the survey, mapping, and GIS industries support a set of requirements that tend to be unique to each applications, thus 'one configuration does not fit all!'

So, where to start?

Start with identifying the applications that you wish to support, as this will help in identifying the UAV airframe you may want to deploy, as well as the sensor payload that you may need to support your UAV applications.

Next, determine if you have the right UAV Airframe

If you have a UAV, you will need to determine if it is the right airframe for your application(s). For example, you’ve decided to support corridor mapping, a market segment where there is a huge upside with the utilities, pipeline and transportation industries. Typically, you will want to use a fixed wing UAV for this application, due to the greater distance that a fixed-wing UAV can cover, as opposed to a multi-rotor UAV. A multi-rotor UAV is much more practical for small area surveys given the limited flying time (e.g. 20 to 30 minutes) that is typical with these platforms.

Selecting a Sensor Payload

Here’s where things get a little more complicated, as today, there are many choices of UAV sensors that are available on the market, ranging from RGB cameras to high-quality LiDAR systems. Think of it this way – your sensor systems need to support your applications.

Let’s look at a few examples:

- RGB Cameras – many UAV operators fly consumer RGB cameras (e.g. Sony A7), as they are relatively inexpensive and can produce high-quality natural color imagery for creating orthophoto maps and digital terrain models, as well as performing inspection and basic image classification. However for high resolution (mm level), high-accuracy data collects to replace ground based GNSS and total station surveying for applications such as railway track geometry and dam deformation, the most accurate and productive solution is to use a medium format metric camera designed specifically for UAV mapping, such as those from Phase One.

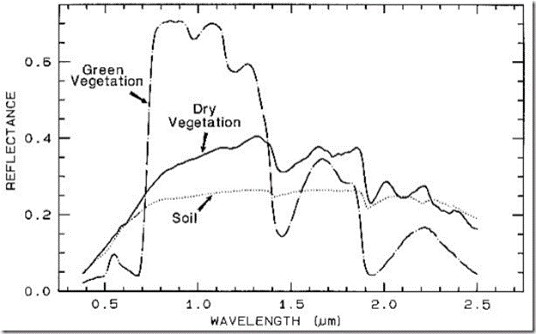

- Multispectral Cameras – these sensors tend to be very versatile and can be used for many UAV mapping and GIS applications. However, they are commonly used for agriculture and vegetation assessment due to the spectral curve mapping that can be completed to determine the health of vegetation and agricultural products. An example of this would be the multispectral sensors from MicaSense.

- Hyperspectral Sensors – these sensors tend to be more specialized due to the enhanced range of spectral bands that can be discriminated. Some key application include mineral mapping and agriculture. Hyperspectral scanners designed for UAV applications are available from such companies as Headwall and HySpex (NEO).

- LiDAR – in recent years there has been a boom in the use of LiDAR scanners on UAV platforms, as LiDAR provides a highly effective tool for 3D mapping and visualization. It is a key application in construction and civil engineering for both quality control and decision-making. Furthermore, RGB imagery can be draped over a LiDAR point cloud for 3D reality modeling purposes. LiDAR’s are available in various qualities, costs, and configurations; the challenge is to select the right LiDAR for your intended UAV applications. Some key LiDAR’s useful for survey and mapping are available from Riegl, YellowScan, and GeoCue.

Collecting your data – the UAV Rover

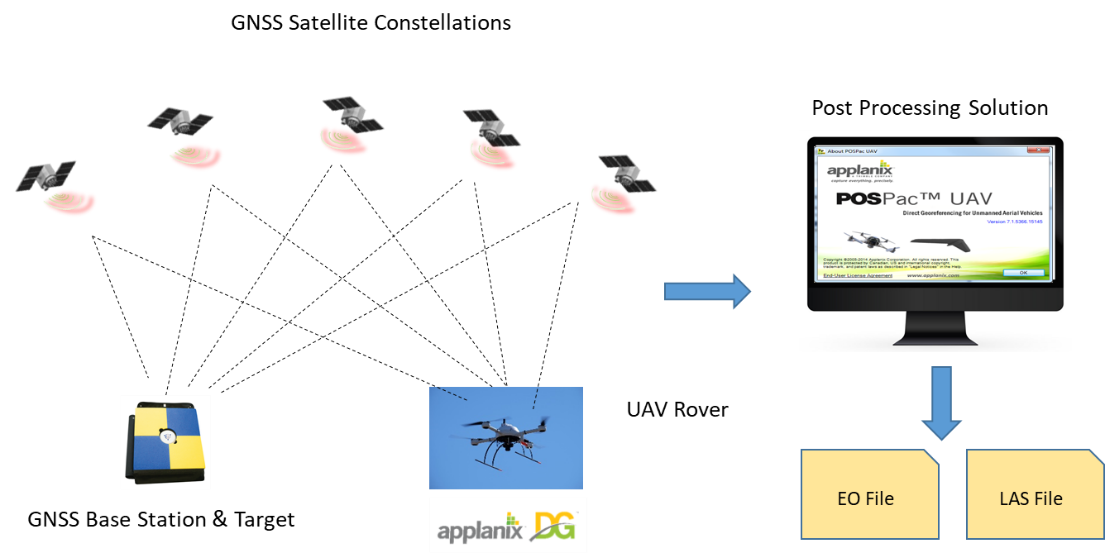

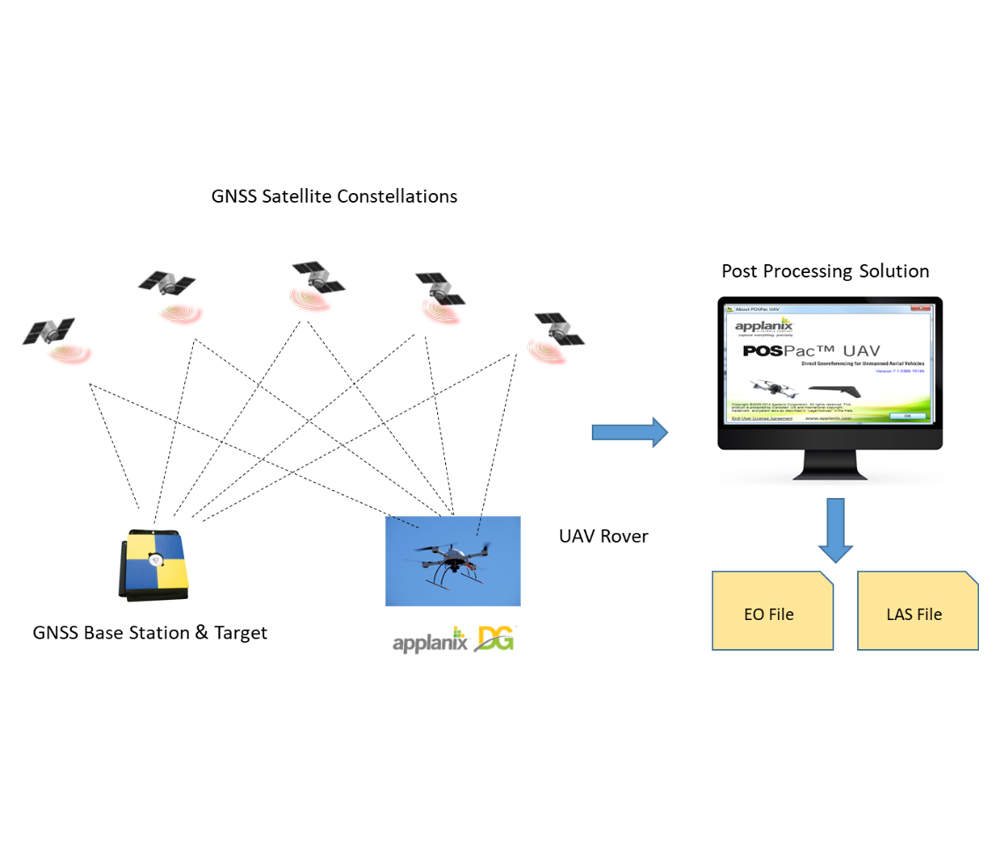

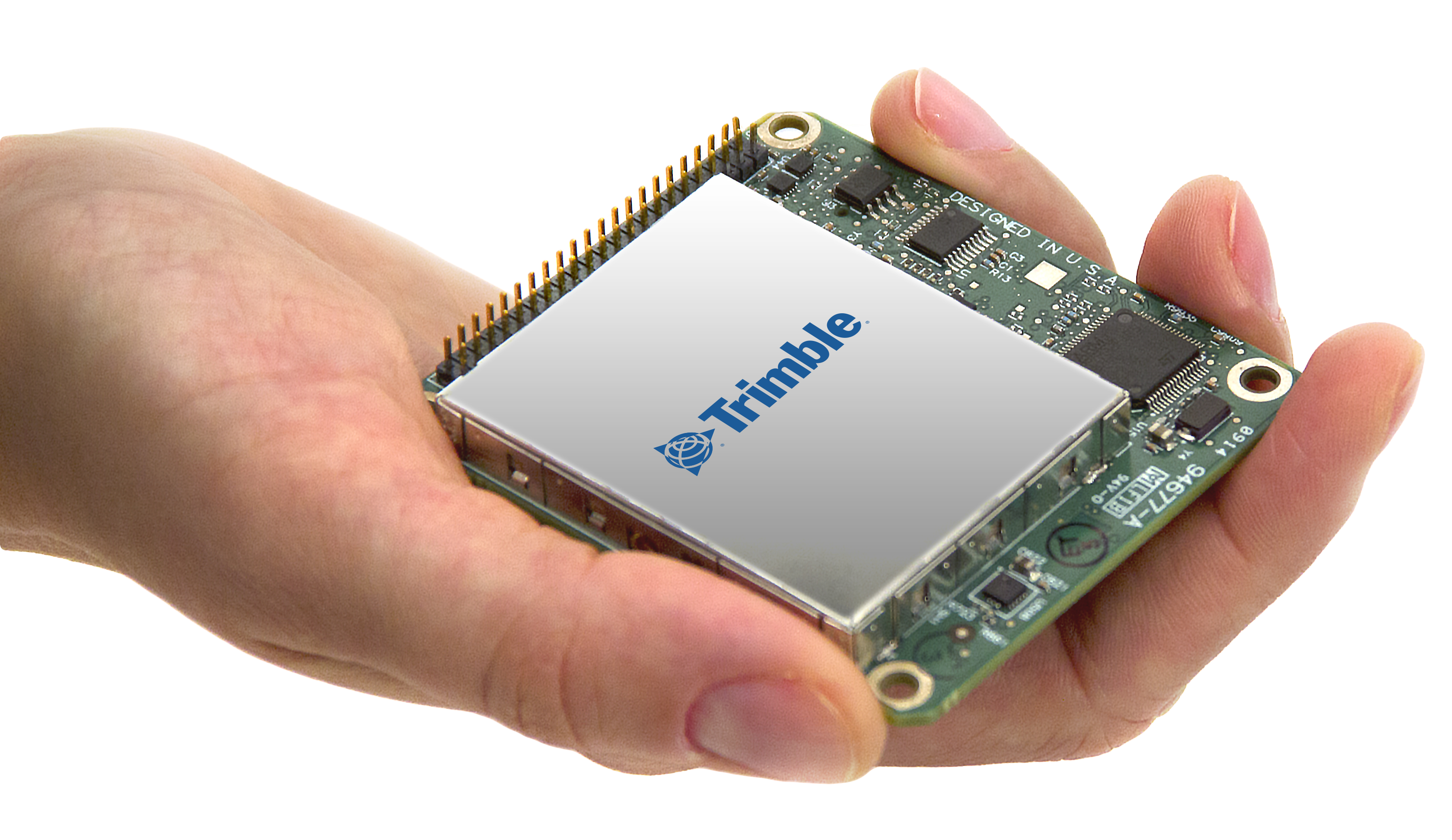

There is a lot more to data collection then just capturing your imagery, you also need to georeference your imagery to its correct geographic position on the ground, so that Surveyors, Mappers, or GIS Professionals can effectively use the imagery data. There are several ways to do this such as tying the imagery to a surveyed network of ground control points, however, the most efficient and cost effective method is to use a process called Direct Georeferencing. In essence, DG directly measures the position and orientation of a UAV sensor, such as a digital camera or laser scanner, thereby making it possible to assign a geographic location on Earth to a pixel from a camera or a digital point from a LiDAR, without the need for ground control points. This is accomplished by capturing both position or orientation data for your imagery using an integrated GNSS/INS, such as the Applanix APX-15 (pictured), mounted on your sensor payload or UAV airframe.

Collecting your data – the Base Station

In addition to the positioning/orientation equipment on the UAV rover, you will also need a GNSS correction method. For this, you will require either a physical base station, a virtual reference station solution, or an augmentation service. An example of a low cost effective base station is the Trimble Smart Target Base Station (pictured).

The Applanix SmartBase module generates a virtual reference station from existing CORS stations, while the POSPac Post-processed Centerpoint RTX (PP-RTX) service uses Trimble high performance global RTX corrections to generate cm accuracy without local base stations.

Processing your data

The final step is to process the data you have collected this includes your imagery, your GNSS/IMU data from your UAV, and your GNSS correction data. This step is typically completed by post processing software, such as with the Applanix POSPac UAV software. The post-processing step results in an Exterior Orientation (EO) file or a LiDAR point cloud - typically a LAS file. These files adhere to industry standards, and can be immediately loaded into any number of product generation applications, such as UASMaster.

Let’s Put it all Together

With your UAV platform – fixed-wing or multi-rotor, sensor payload, and Direct Georeferencing technology along with post processing software in place, you have effectively turned your UAV into a low-cost, highly efficient professional grade survey and mapping solution compatible with a range of cameras, LiDAR’s and other mapping sensors.